| Improving speed and accuracy |

|

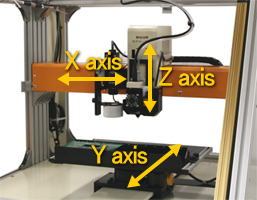

High speed, high accuracy and strangeness are realized by changing belt

drive into ball gear drive. High speed, high accuracy and strangeness are realized by changing belt

drive into ball gear drive.

Improving 1.6 times moving speed of XY table. Improving 1.6 times moving speed of XY table.

Repeatability is improved up to 4 times Repeatability is improved up to 4 times |

| Wider XY stroke |

Supporting up to size M board(330 x 250mm) Supporting up to size M board(330 x 250mm) |

| |

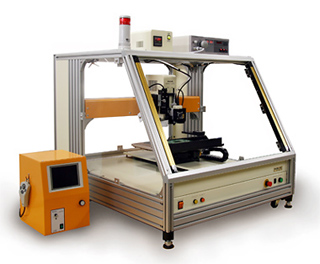

| Improving safety |

|

Acrylic cover, Indication lamp and buzzer are equipped. Acrylic cover, Indication lamp and buzzer are equipped.

Area sensor (light curtain) is equipped at the front. Area sensor (light curtain) is equipped at the front. |

| |

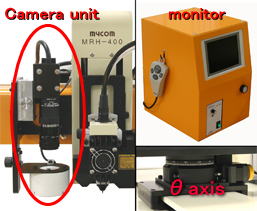

| Image recognition unit |

|

High accurate solder paste painting is realized by compensating 3 axes

of X, Y and θafter reading fiducial mark of board with camera unit installed

at head. High accurate solder paste painting is realized by compensating 3 axes

of X, Y and θafter reading fiducial mark of board with camera unit installed

at head.

Test mode is equipped and it is available to show enlarged painting results

at special monitor. Test mode is equipped and it is available to show enlarged painting results

at special monitor.

|

| |

| Z axis detection and compensation instruments |

|

High accurate cream solder painting is realized by automatic measurement

of degree of bent board to paint by laser displacement sensor installed

at Z axis. High accurate cream solder painting is realized by automatic measurement

of degree of bent board to paint by laser displacement sensor installed

at Z axis. |

| |

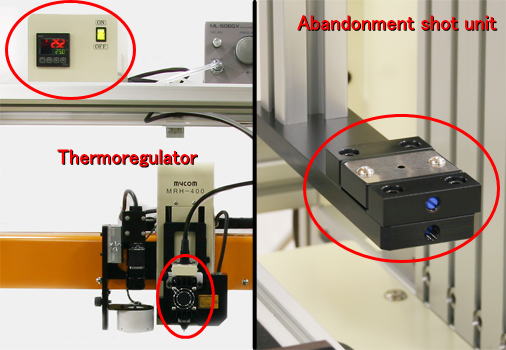

| Temperature adjustment instruments |

Temperature adjustment instruments are devices to adjust solder paste into

best suitable temperature for painting and keep same temperature.

|

Abandonment shot unit

|

There is a case that first shot is stopped and difficult to output painting

solder paste. This trouble is solved by preparing abandonmentt shot and

realizes uniform painting.

|

日本語ページはこちら (Japanese here)

日本語ページはこちら (Japanese here)